Hearing Protection

Request a quote for otoplasticsHearing Protection

Request a quote for otoplasticsHearing protection is essential

It is well known by now that loud and/or prolonged noise has a harmful impact on humans. The hair cells in the cochlea that transmit sound to the brain become damaged and eventually die when exposed to high sound pressure for long or loud enough. This results in hearing loss, tinnitus (phantom sound) and hyperacusis (hypersensitivity to sound). Noise also has non-auditory health effects. Here, stress, blood pressure, cardio-vascular disorders, loss of concentration, overtiredness and irritability have become general keywords.

Countless organisations face such harmful noise levels in production areas. These organisations are therefore morally and often legally obliged to protect their employees from this. Besides a technical approach such as source control or administrative measures, such companies also choose to offer hearing protection. Here, the most logical choice goes to the safest and most comfortable type of hearing protection: otoplastics (custom-made earplugs).

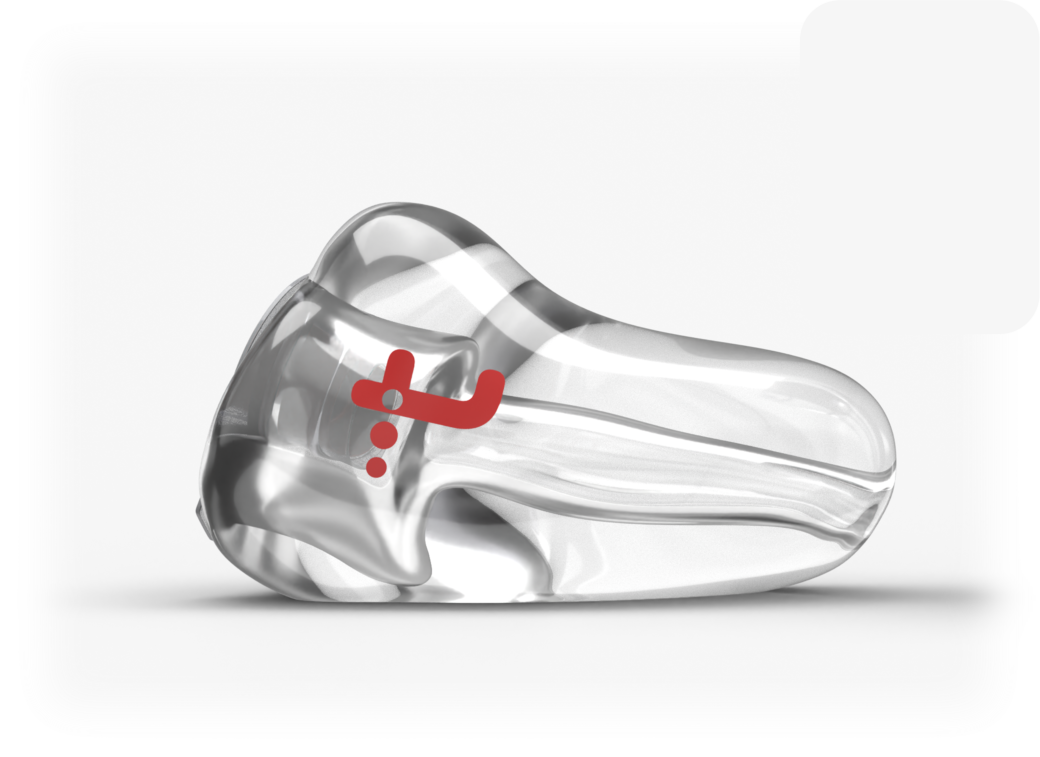

Otoplastics

Otoplastics are the most comfortable type of hearing protection and therefore also the safest. In fact, comfort has a proven effect on user acceptance, making them worn faster and longer. By comfort, we first mean a good fitting. Our otoplastics are manufactured with extreme precision using the latest 3D technology, resulting in a perfect fit. Secondly, comfort is determined by good speech understanding and spaciousness. Tympro's filters are designed with these properties in mind.

Besides comfort, otoplastics are also the most durable and economical choice. Thanks to their long service life, waste is significantly reduced and direct costs for the company over their lifetime are lower compared to other types of hearing protection. Indirect costs also decrease as comfortable earplugs increase productivity and reduce absenteeism.

Tympro Orange

The Tympro Orange is our set of custom-made silicone earplugs that feature a large-surface breathable membrane filter. This attenuating membrane is designed to allow sound to pass through as naturally as possible. The natural transmission of sound benefits the understanding of complex speech sounds as there is less distortion. The sense of spaciousness is also maintained. Several fixed attenuation levels are possible, with the selection depending on the sound environment and the need for communication. A hard version of the Tympro Orange in acrylic also exists.

Request a quote here.

Tympro Food

To ensure food safety, additional regulations apply in the food industry regarding hearing protection. Tympro offers such companies the Tympro Food, a variant of the Tympro Sound Safe. These otoplastics have the distinctive blue colour and feature a metal detectable ball. The version is standard in acrylic which makes them more cleanable and thus more hygienic than the silicone variant. Finally, these earplugs come with a detectable cord with clip as standard. Losing them is not an option.

Tympro Cord with Clip

The Tympro Orange feature the Tympro Cord with Clip. The design is unique in that it allows the user to easily attach and remove the cord themselves. By pulling the end of the cord through the arch of the otoplastic, the arch will attach itself at the level of the recess in the cord. In addition, the thickening on the right side provides its own tactile and visual check for the correct position of the otoplastics.

Maximum service

We go to extremes when it comes to service. On a regional basis, our customers have a fixed contact person from our office sales team and a product specialist from our field sales team. There is a well-oiled coordination between inside and outside sales, which ensures extremely efficient planning and support for the customer.

In consultation with the customer, the office staff schedule a time for the product specialist to visit the customer free of charge to take ear impressions. As soon as the earplugs go into production, a second time is scheduled for the product specialist to deliver the otoplastics on site. During delivery, the specialist gives clear instructions and performs a leak tightness test on the otoplastics.

Maximum comfort

Otoplastics with the perfect fit offer the most comfort in the ears. To achieve this perfection, Tympro monitors every step of the production process for quality. It starts with the periodically trained product specialist taking perfect ear impressions. The lab technicians employ the latest 3D and AI technology to scan the impressions, model the scans and finally print them out. During delivery, the product specialist tests the otoplastics for fit and leak tightness. The otoplastics are certified to EN 352-2 and the business process to ISO 9001.

Annual maintenance

The shape and size of the outer ear are constantly changing. As a result, after a few years otoplastics no longer completely seal off the ear canals, creating a risk of leakage and thus a risk of hearing damage. The user often does not notice this himself. The leakage occurs at a different time for everyone. In addition, the inner structure of the otoplastics can become clogged with earwax or dirt, which affects the attenuation.

Because of this, Tympro recommends annual maintenance on otoplastics. For this, our product specialist comes on site for a 5-minute consultation per user. He enters into a dialogue with the user. He then performs a thorough cleaning, replaces the noise filter and resets the attenuation of the otoplastics. Finally, the leak tightness test will determine whether the otoplastics seal properly. The specialist makes new impressions only in case of a leakage or defect.

Let our experts advise you

Would you like us to personally assist you in selecting hearing protection and accessories or to clearly explain what our service entails and how we can tailor it to your business needs? We will be happy to speak to you on the phone with no obligation or to visit you if you wish.

Frequently asked questions about our hearing protection and our service

On average, otoplastics last for 5 years. Because the outer ear changes differently and at different rates for everyone, the individual lifespan can vary greatly from person to person.

That is why we recommend performing an annual leak test instead of replacing the otoplastics after a fixed number of years. This has two major advantages:

- Safety: You prevent someone from walking around with leaking earplugs for years (false sense of security).

- Cost savings: You only replace the otoplastics when they really no longer seal properly, and not unnecessarily early.

We provide custom-made hearing protection in six steps.

- Contact & assessment: You contact us. We will assess your specific requirements, the number of users and your preferences.

- Quotation: Based on this conversation, you will receive a suitable quotation.

- Planning: After you have agreed and completed the customer form, we will schedule an appointment with our product specialist in consultation with you.

- On-site measuring: Our specialist will visit you. He can measure approximately 10 people per hour.

- Production: The ear impressions are processed into otoplastics in our laboratory.

- Delivery with leak test: We will return within four weeks of the initial assessment to deliver the sets. We will provide instructions and perform a leak test to guarantee 100% safety.

The maintenance session will be completely useless without the users. The most important part of the maintenance is the leakproof test. During this test, the product specialist tests whether the otoplastics still blocks the ear canals adequately. In addition to this, the dialogue between the user and the product specialist is very important. Based on the experience, adjustments, such as the damping, can be made.

The product specialist delivers the otoplastics on site. Upon delivery, an instruction is given and the otoplastics are tested for leak-tightness. If the otoplastics show a leak, new ear impressions can be taken immediately. The user can also immediately indicate whether the otoplastics feel good or not. The specialist also supports the user in the exercise to insert the otoplastics properly. We therefore strongly recommend a presence of the users. Suppose someone is unexpectedly absent, we leave the otoplastics set up and test them during another appointment.

The choice between hard and soft otoplastics depends on the working environment, hygiene requirements and personal preference.

Hard otoplastics (acrylate): These are made from a hard, durable plastic.

- Superior hygiene: Due to their smooth surface, dirt, earwax and bacteria hardly adhere to them. They are very quick and easy to wipe clean. Due to their high cleanability, hard otoplastics are preferred in the food sector.

- Easy insertion: Because the material is smooth, they slide effortlessly into the ear. This is ideal for employees who frequently need to insert and remove their hearing protection (e.g. managers).

- Fit & movement: Because the material is rigid, it does not bend. If you talk or chew a lot, it can sometimes feel uncomfortable and a tiny gap can sometimes form, allowing sound to leak in.

- Durability: Hard ones are less prone to normal wear and tear, making them the most durable, but they can crack or break more easily if dropped on a hard concrete floor.

Soft otoplastics (silicone): These are made from flexible silicone material.

- Maximum comfort: The material is soft and flexible. This reduces the risk of pressure points or irritation in the ear canal, making them ideal for long shifts.

- Constant protection: Because silicone is flexible, it moves with the ear canal. Even when you talk, laugh or chew, the seal remains intact.

- Comfort and safety under the helmet: Soft material is more comfortable and safer for wearers of safety helmets. In the event of a blow to the head, the material gives way instead of passing the impact on to the ear.

- Slightly more difficult to use: Silicone has more friction: it does not slide over the skin. Insertion sometimes requires a twisting motion, and it can attract dust more quickly if touched with dirty hands.

- Slightly smaller occlusion effect: Because silicone is flexible and has a lower density than hard acrylic, it absorbs vibrations from the ear canal wall better. This often makes your own voice sound more natural and less muffled.

- Durability: Soft otoplastics wear out a bit faster and don't last as long. They also tend to discolour over time. But they're more shock-resistant and pretty much indestructible if dropped. They bounce instead of breaking.

In summary:

- Choose hard if hygiene is crucial (food), if the earplugs need to be inserted and removed very often, and if they need to last as long as possible (durability).

- Choose soft for maximum comfort during long days, when talking/moving a lot, or in heavy industry/construction where a helmet is worn.

Applying a standard replacement period (e.g. every 5 years) for otoplastics is neither the safest nor the most cost-effective strategy.

This is because the outer ear changes in a unique way and at a unique speed for each individual. As a result, the actual lifespan of otoplastics varies greatly from person to person.

The risks of a fixed replacement period are twofold:

- Risk of hearing damage (false sense of security): In some users, the ear canal changes more quickly, which means that otoplastics can start to leak after only two years, for example. If they are not replaced until after five years, the employee will have been walking around with a false sense of security for three years, which can lead to irreversible hearing damage.

- Unnecessary costs (waste): For other users, the fit remains good for much longer (e.g. 8 years). If these otoplastics are discarded preventively after 5 years, the company incurs unnecessary costs for replacement that was not yet necessary.

What is the best alternative to a fixed replacement?

Instead of blindly relying on a calendar year, annual checks are the gold standard.

- Annual leak test: By testing earplugs for leaks every year, you can be sure that they still provide adequate protection. Leaky earplugs are replaced immediately, while earplugs that are still in good condition remain in use.

- Maintenance and dialogue: A maintenance appointment provides an important opportunity for contact between the specialist and the wearer. Any complaints, comfort or hygiene issues can be resolved immediately. The filter and the earplug channel are cleared, eliminating any excessive attenuation. This has a positive impact on wear acceptance.

The otoplastics are delivered within 4 weeks after the time of measurement. Tympro takes care of the delivery itself, whereby the specialist gives personal instructions to the new user and performs a leak-tightness test on the otoplastics. The leak tightness test is only possible if the user is present, as the otoplastics are tested in the ears.

In South Africa, the rules are governed by the Noise Exposure Regulations, 2024. Companies should focus on two distinct thresholds: the standard Noise-Rating Limit and the more specific Noise Action Level.

1. The critical thresholds

The law defines specific levels at which an environment becomes a 'noise zone'. If your workplace meets these criteria, strict obligations apply.

- The standard limit (Noise-Rating Limit):

Continuous noise: An 8-hour rating level (LEX,8h) of 85 dBA or higher.

Impulse noise: A peak noise level (LCpeak) of 137 dB(C) or higher.

- The lower limit (Noise Action Level):

- This applies specifically if employees are also exposed to ototoxic chemical agents (chemicals that damage hearing) or whole-body vibration.

Continuous noise: An 8-hour rating level of 82 dB(A) or higher.

Impulse noise: A peak noise level of 135 dB(C) or higher.

2. Obligations in a 'noise zone'

If an area or a piece of machinery exceeds the limits mentioned above, it is legally classified as a noise zone.

Mandatory entry: No person is allowed to enter or remain in a noise zone unless they are wearing effective hearing protective devices (HPDs).

Demarcation: The employer must clearly demarcate these zones (or mobile machinery) with visible signage.

Employee duty: Employees are legally obligated to inspect, use, and wear their HPDs strictly in accordance with training and instructions.

3. Requirements for the protection (HPDs)

It is not enough to simply provide earplugs. The regulations require specific performance standards from the protection provided:

Effectiveness: The HPDs must be capable of reducing the noise exposure to below the noise-rating limit (below 85 dBA).

Combined risks: If working with ototoxic chemicals or vibration, the HPDs must reduce exposure to below the noise action level (below 82 dBA).

Selection criteria: When choosing protection, the employer must consider comfort, the physical effort of the work, and compatibility with other safety gear (like hard hats or goggles).

4. The hierarchy of control

South African law emphasizes that hearing protection is the last resort, not the first solution.

- Eliminate: The employer must first try to eliminate the noise source.

- Mitigate: If elimination is impossible, they must use engineering controls (like silencers or enclosures) or administrative controls (limiting the time spent in the noise).

- Protect: Only if these measures fail to reduce noise below the limits must HPDs.

5. Important tip:

Be aware of the "Combined Risk." The 2024 Regulations place a heavy emphasis on Ototoxic Chemical Agents (chemicals that can cause hearing loss even below 85 dB). If your staff works with solvents, heavy metals, or asphyxiants and noise levels are around 82 dB, you are legally required to treat that area as a full Noise Zone and enforce hearing protection.

In the food industry, food safety is the highest priority. Hearing protection must therefore not only protect hearing, but also eliminate the risk of physical contamination (foreign particles in the food). To comply with strict quality standards such as HACCP, IFS and BRCGS, hearing protection must meet four crucial requirements:

- Metal detection (traceability): In the unlikely event that an otoplastic falls into the production line, it must be detected immediately by the detection systems. Standard plastic is not detected by metal detectors. That is why a steel ball is incorporated into the design. This ensures that the final check (the metal detector) stops the line if the earplug ends up in the product.

- Visual detection (use of colour): Blue is a colour that does not occur naturally in foodstuffs. For this reason, blue is the industry standard. This ensures maximum contrast, allowing employees or visual inspection systems to immediately detect a lost ear mould on the conveyor belt or in the product.

- Hygienic material (recommendation: acrylic): In environments where bacteriological risks must be minimised, Tympro recommends the use of hard acrylic.

- Why acrylic? Unlike softer silicone materials (which can be more porous and age more quickly), acrylic has a smooth, hard and non-porous surface.

- Cleaning: This makes the otoplastics very easy to clean and disinfect, which is essential to prevent cross-contamination. Acrylic is therefore the most hygienic choice for the food industry.

- Anchoring (cord with clip): Prevention is better than detection. That is why we always recommend using a cord with a clip. This prevents an otoplastic from falling on the floor or into a machine if it slips out of the ear.

- Specifications: This cord must also meet the detection requirements: it must be blue and contain detectable material (such as metal particles).

When determining the damping values, first and foremost, the protective base is taken into account. This is determined based on the sound levels in the company. We base this on noise reports prepared in the past by us or by another party. If there are no measurements of this, we will make an estimate based on the industry and activities. Secondly, the avoidance of overprotection (too large attenuation value) is always taken into account, which in itself leads to higher acceptance of the hearing protection, which is of course beneficial for hearing health. The manageable attenuation values of otoplastics have an adjustment range between 20 dB and 35 dB.

The auditory canal has a self-cleaning mechanism whereby earwax is expelled naturally. In some people, this process regularly goes wrong and earwax continues to accumulate, causing a hardened cerumen plug.

A clogged ear is an important reason for not having a fitting. If the product specialist wishes to insert a cotton wool and inject mould paste into the ear canal, there is a risk that the hard and sometimes sharp cerumen plug will be pushed in even further and damage the eardrum. In addition, the ear impression will not be representative enough to make a good otoplastic from it.

If Tympro will visit soon to take ear impressions, it is advisable for people who regularly have cerumen plugs to visit their GP (just) before the appointment to remove the cerumen plug. Otherwise, there is a risk that the staff member and the product specialist will have to make a second fitting appointment with each other. So keep each other well informed about Tympro fitting times.

Customised earplugs, also known as otoplastics, are personal hearing protectors that follow the exact shape of your ear canal. Because they are produced specifically for your ears, they offer optimal sealing and the highest possible wearing comfort without pressure points. These properties make otoplastics superior to universal earplugs. Our approach combines craftsmanship with innovative 3D technology:

- Ear impression or ear scan: A specialist will make an exact impression of your ear using silicone material or create a digital 'impression' using an ear scanner.

- 3D production: In the case of a physical impression, the ear impression is digitally scanned and then modelled using software. In the case of an ear scan, the 3D file of the ear is transferred to the software for direct modelling. We then print the earplug with extreme precision in hard acrylic or soft silicone.

- Filter placement: The earplugs are fitted with a professional filter. This filter is designed to attenuate harmful noise while allowing speech and warning signals to remain audible.